THREADED INSERTS

|

|

|

| Zinc Flanged | Brass | Zinc Un-Flanged |

There are many applications where a machine thread is required in wood. Threaded inserts are very useful because any assembly put together with them can be dismantled. They are therefore perfect for prototypes, jigs and permanent assemblies which are more rarely broken down but which require this feature as a part of the design brief.

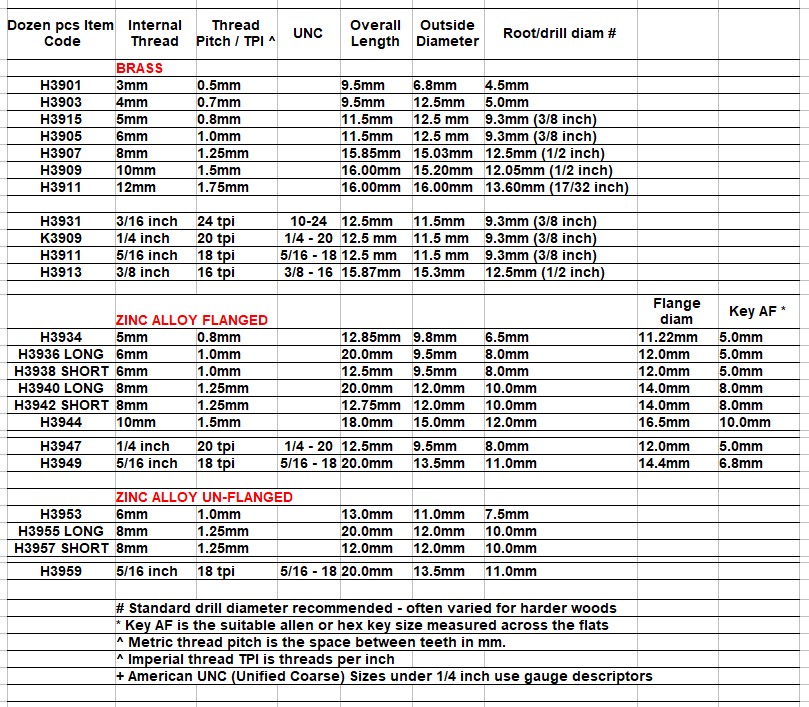

INTERNAL THREAD

Thread options internally are applicable world wide and either METRIC measured in millimetres or imperial inch sizes in UNC/WHITWORTH. They are incompatible with each other.

(UNC = Unified Coarse is a standard used in America and confusingly uses gauge numbers for sizes under 1/4 inch. What we in Australia may know as a 3/16th inch may be referred to as a 10--24 in US publications - a 10 gauge screw with 24 teeth to the inch).

EXTERNAL 'THREAD'

The external threads on these inserts do not follow any standard that I am aware of and threading taps are unavailable

THREAD PITCH

Thread pitch is a measure of the distance between adjacent teeth. Metric pitches are simply measured in millimetres, UNC/Whitworth pitch is a count of the number of threads to an inch of the screw.

Standard Metric Coarse (there is a Metric Fine - rarely encountered) are as follows:

- M3 x 0.5mm

- M4 x 0.7mm

- M5 x 0.8mm

- M6 x 1.0mm

- M8 x 1.25mm

- M10 x 1.5mm

- M12 x 1.75mm

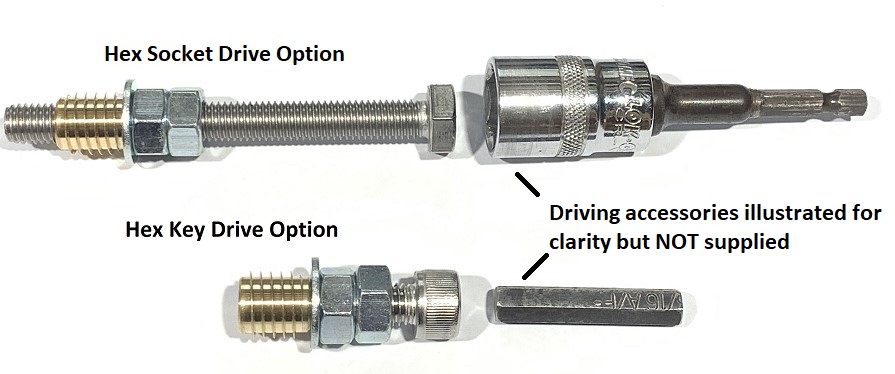

INSERTION

All inserts are best seated using a mandrell as below. The zinc versions can be seated using a up-scale allen key although experience suggests a mandrell is a better option. The brass inserts may have a slot for an insertion tool which we don't offer. We do not suggest the use of a screwdriver which may chew up brass inserts.

The root diameter is the diameter of the insert at the bottom of the external teeth and is the minimum diameter of the drilled hole required.

The insertion hole is often slightly varied to accommodate harder woods

Inserts can be inserted at an angle. A pre-drilled, angled, landing flat assists with this, drilled with either a forstner or spade bit.

Given a long enough insertion mandrell it is possible to gang 2 inserts together for greater holding strength. It may be wise to have a machine tap to finish the job. You can seat the inserts with a little adhesive taking care not to get glue on the internal threads.

MANDRELS

See HERE

This is the suggested rig for setting both brass and zinc alloy inserts. You can use a ratchet handle in lieu of the hex detent shank drive adaptor. Be sure the washer is used in reverse, polished side against the insert. A dab of oil internally on the insert can also ease release of the mandrell.

For those users who may find it difficult to source large set screws (a SET SCREW is a full thread BOLT) we offer mandrels in M4 through M12 and 4 imperial thread sizes

Dimensions and drill selection:

Note; Due to supply issues we occasionally source inserts with varying external dimensions. If you are not equipped to manage these variations please confirm the dimensions of current stock.

Click HERE to see a comprehensive data sheet.

See HERE for a data sheet with links to over 75 of our specialised fasteners

===============================================================

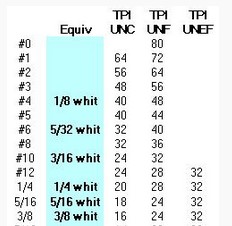

AN EXPLANATION OF INCH THREAD OPTIONS

Unified Thread System (UNC) and British Standard Whitworth (BSW)

There is approximate compatability between UNC and BSW for sizes under 1/2 inch and with the decline in use and availability of BSW it is probably best to use UNC.

Some references to thread specifications cause confusion for Australian readers.

This is largely because the UNC standard drops the use of inch fractions and uses gauge numbers for sizes under 1/4 inch.

It is not immediately clear that an #4-40 UNC designated screw will be a close enough fit for what Australians would know as 1/8 inch Whitworth.

This subject is as deep as you want to delve but a quick summary is as follows.

=============================================================================

Inserts for metal

|

|

|

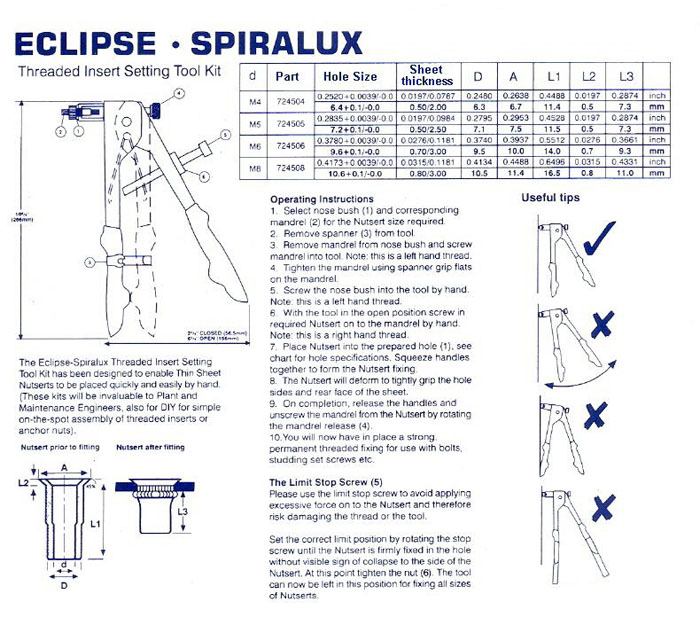

Our inserts for metal sheet require a setting tool. See Item Code: T8358. This British made setting tool is supplied in a kit with a selection of metric 4, 5, 6 and 8mm thread inserts. Click HERE for additional inserts.

The application is identical to using a pop riveting tool and can be carried out entirely from one side of the work

Drill an appropriate diameter hole (note the tolerance here is quite tight, you must source a correct size drill), insert the correct mandrell for the insert in the pliers (take care, some of the parts have a left hand thread), wind on the insert and set the insert as you would a pop rivet taking care not to over tighten the setting tool.

Kit Instructions

Last edit: 30/08/21