Japanese chef knives - generically known as hocho - have an unrivalled reputation for edge quality and retention and possess jaw droppingly beautiful aesthetics.

There are several manufacturing - or perhaps a better word is making - techniques because the best and most revered of these hocho are hand made by master smiths who take the build and aesthetic qualites of these hocho way past any mere functional requirement.

- For purchase details for 25 different makers and styles see HERE

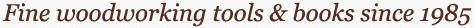

A Hocho Santoku with Western Design influences. A santoku is a general purpose knife and a good first purchase.

There are two general classes, honyaki where the blade is made from one homogenous material (the standard western approach) and kasumi, the more renowned method where a core of high carbon steel - usually blue paper or white paper steel known generically as hagane - is forged with cheeks of soft iron jigane steel often recycled from old anchors, rail bridges and the like. This method gives these knives, and numerous other Japanese edge tools, their descriptor as 'laminated'.

This layered construction, in the case of dual bevelled hocho, provides an extremely hard, high quality, edge holding, core layer of usually non rustproof steel sandwiched by softer cheek steel. The jigane cheek steel, often patinated from the forging process and containing irregularities, serves to cushion the hard and brittle core, to render the majority of the surface of the hocho rustproof, to allow the incision of the maker's 'chop' or insignia and to contribute to the aesthetic appeal of the hocho.

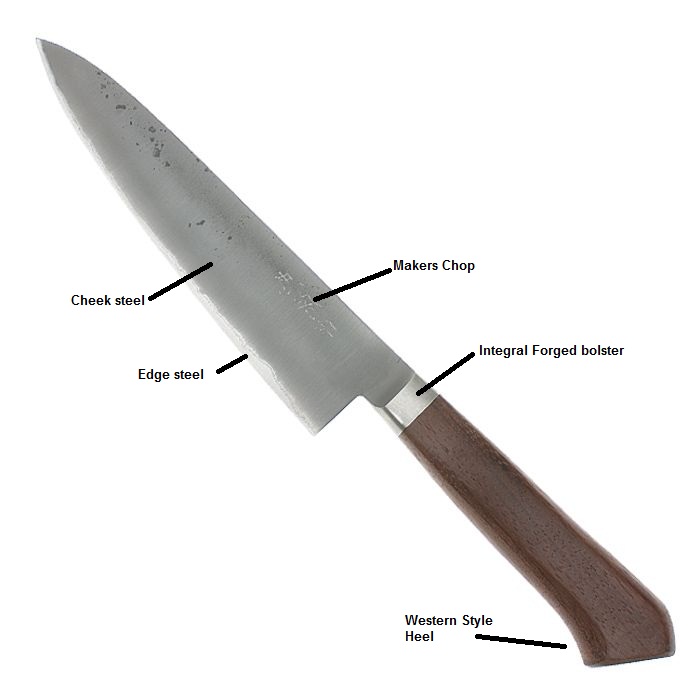

A few hocho options - for example the Deba - are single bevel and constructed from one layer of edge steel and cushioned on one side only.

A subset of the kasumi class are the high-grade quality knives called hongasumi which are fabricated with multilayer Damascus steel. Many of these are rustproof and, although within the meaning of the term are 'stainless', they are in a class way beyond western common and garden stainless knives. The hardest of these have an astounding HRC of 66 and are composed of as many as 73 layers. They are often etched to reveal the damascus patterning and many have hammered patination on their cheeks.

Bear in mind that quality edge tools which use high carbon or tool steel for their cutting edges in woodworking, gardening and the kitchen are subject to rust. A susceptibility to rusting is an unavoidable trade off for the edge taking and holding nature of high carbon steels. It is also a truism that the harder steels get the more brittle they become. These knives are not therefore intended for frozen meats or fish and should scrupulously be kept away from metal such as sinks or other metal kitchen implements. If you appreciate the functional and aesthetic character of these blades you may need to become the knife nazi in the kitchen when it comes to care and maintenance.

Stock Note: We list a wide selection of Hocho and many are made to order and not held in stock. Please contact us for likely delivery timing. These knives are artisan made and not mass produced.

Care & Maintenence

- See HERE for recommended Japanese water stones for sharpening and honing.

- See HERE for for Keshigomu abrasive rubbing blocks for polishing.

- See HERE for storage and mothballing options.

- For purchase details for 25 different makers and styles see HERE

===================================

In this data sheet

- The typical design elements

- A summary of the styles of Hocho

- Hardness - what does HRC mean?

- White Paper, Blue Paper and Damascus steels

- What is Urushi

Design Elements

We offer both traditional Japanese styled Hocho and Western design hocho. The major design differences involve the handle which with Japanese styles is usually pressed onto a tang integral with and concealed by the handle and with Western styles composed again of a revealed tang integral with the blade fitted with cheeks or scales held in place with cutlers rivets.

Handles Although there are many exceptions Japanese style Hocho usually have handles which are pressed on to a tang which is an extension of the blade and western design hocho have handles with the blade material similarly taken right through the handles with cutlers rivets holding a 'scale' each side of the blade to form the handle

Handles can be made from wood or pressurised wood e.g. linen micarta, in round or octagonal section and, in one instance, made from pressed birch bark.

Exceptional handles may be urushi varnished.

Heels Japanese hocho sometimes have added heels but in the main handles are unheeled. Western design hocho may have a more shaped handle with a pronounced heel.

Bolsters Some bolsters are forged as one with the blade, many are a piece of exotic or especially attractive wood added to the handle wood and many more have a buffalo horn bolster. Note that there is rarely if ever any guarding between the handle and the blade.

Blades Many Japanese Hocho, whether they be in a traditional Japanese style or a Western style, use a laminated blade where the core of the blade is high carbon, non rustproof edge holding steel. The very hard and relatively brittle core steel is flanked by cheeks of softer rustproof steel which cushions the core steel. Many makers patinate the cheek steel with hammer marks and the cheeks are soft enough to take the makers chop or insignia.

Other blade options are stainless and fabricated with exotic multi layered and etched damascus steels .

The Main Hocho Styles

|

Typical Specification |

Example Picture |

| Santoku - General Purpose

Dual bevel Overall - 310mm Blade length - 165mm Blade thickness - 2.2mm

|

|

|

Petty - General Purpose Dual bevel Overall - 230mm Blade length - 115mm Blade thickness - 2.0mm |

|

|

Gyuto - Fish & Meat Dual bevel Overall - from 240 to 315mm Blade length -120 to 180mm Blade thickness - 1.8mm to 2.7mm |

|

|

Usuba - for Vegetables Dual & Single bevel Overall - 300mm Blade length - 165mm Blade thickness - 1.8mm |

|

|

Sashimi - for Sashimi Right Hand Single bevel Overall - 380mm Blade length - 230mm Blade thickness - 3.5mm |

|

|

Deba - General Purpose Right Hand Single bevel Overall - 310mm Blade length - 180mm Blade thickness - 6.5mm |

|

|

Ajakiri - General Purpose Dual bevel Overall - 230mm Blade length - 105mm Blade thickness - 2.8mm |

|

For purchase details for 25 different makers and styles see HERE

Hardness - The Rockwell Scale

The HRC hardness scale for metals used across many industries is, simply put, the measurable degree to which, under 150kg pressure, a very hard tungsten ball or cone shaped diamond penetrates the material under test.

There are 7 Rockwell ratings, HRA, HRB, HRC, HRD, HRE, HRF and HRG. The HRC rating is the one most commonly used and referenced in woodworking and kitchen edge tooling.

The question often arises is the Rockwell scale linear or logarithmic or exponential or does it obey some other rule. In other words how much harder is a RC63 to RC60. The answer is far from simple and outside the scope of these short notes but suffice to say it is not linear. Intuitively a spherical ball or cone will have an increasing non linear resistance as it is pressed further into any material. It follws that a couple of points on the HRC scale is very significant.

Reference source Felix01 from http://www.knifeforums.com/forums/printpost.php?tid/418945/

Unlike most things we typically measure, hardness has no absolute scale. But when conducting Rockwell (C) measurments, the penetration of a spheroconical diamond (120� cone with a 0.2mm radius tip) under a (major) load of 150 kg of force (330 lbs) is measured and converted reciprocally into a Rockwell hardness number. The smaller the penetration, the greater the hardness; thus, the higher the Rockwell number. According to the ASTM (American Society for Testing & Materials), one Rockwell number represents a penetration of 0.002 millimeter (0.000080 inch).

Many tools, knives and blades found in woodworking, gardening and the kitchen will have HRC readings of between about 40 and 66. All the hocho we market will fall into a band approximately HRC62 to HRC66.

Some typical tools

Western hand saw - 38 to 42

Cabinet scraper - 50

Axe - 45 to 55

File or rasp - 62

Western chisels - 58 to 62

Japanese chisels - 60+

Japanese hocho - 62 to 66

White and Blue Paper Steels

The term white and blue paper steels arises from the packaging used by Hitachi which makes the traditional paper steels.

In summary Blue Paper steel is a regular High Speed Steel and White Paper steel has some additional Tungsten and Chromium added.

The classification and composition of edge taking and holding steels is a complete and still evolving science. Characteristics of interest include the hardness (tungsten carbde excels), the toughness or ability to take a viable edge, (tungsten carbide is poorer than HSS), the ability to retain an edge after hot work (HSS air hardens after becoming hot under use, regular tool steel may air anneal - soften - after becoming hot under use) and the workability which means how easy is it to sharpen.

Reference Source Rottman in http://www.kitchenknifeforums.com/archive/index.php/t-2362.html

In Carbon there's two varieties of paper steels: Shirogami (white paper, plain carbon) and Aogami (blue paper, some Tungsten and 0.5 Chromium added). A main feature are the low values of Sulfur and Phorsphorus. Both come in two grades No.1 and No.2 (~1.05-1.15 C), the No.1s have 0.2 more Carbon and are rarely seen compared to the easier to work with No.2 varieties. In addition there's also Aogami Super with higher Carbon (1.4-1.5) more Tungsten, some Mo and V. For compositions check this (http://zknives.com/knives/steels/steelchart.php), search for "white 1", "blue 2" etc.

The Very Old and the Very New - Damascus and Powder Matallurgy Steels

Damascus steel is the stuff of legend - see below.

Modern Damascus steels are made by repeated folding, re-forging and re-pressing layers sometimes with twisting added and finally etching the finished blade to exhibit the patterns of the layer.

The use of powdered metallurgy - PM steels - is evident in some knife steels although the use of tungsten carbide (TCT) is not because it is a sintered matrix and cannot hold acute edges without shattering. TCT tooling has no presence in knife blades although does have remarkable durability with the use of much blunter edges.

Reference Source Wikipedia

Powder metallurgy is the process of blending fine powdered materials, pressing them into a desired shape or form (compacting), and then heating the compressed material in a controlled atmosphere to bond the material (sintering). The powder metallurgy process generally consists of four basic steps: powder manufacture, powder blending, compacting, and sintering. Compacting is generally performed at room temperature, and the elevated-temperature process of sintering is usually conducted at atmospheric pressure. Optional secondary processing often follows to obtain special properties or enhanced precision.[1] The use of powder metal technology bypasses the need to manufacture the resulting products by metal removal processes, thereby reducing costs.

Reference Source Wikipedia

Damascus steel was a type of steel used in Middle Eastern swordmaking. Damascus steel was made from wootz steel, a steel developed in India around 300 BC.[1] These swords are characterized by distinctive patterns of banding and mottling reminiscent of flowing water. Such blades were reputed to be tough, resistant to shattering and capable of being honed to a sharp, resilient edge.[2]

The original method of producing Damascus steel is not known. Because of differences in raw materials and manufacturing techniques, modern attempts to duplicate the metal have not been entirely successful. Despite this, several individuals in modern times have claimed that they have rediscovered the methods in which the original Damascus steel was produced.[3][4]

The reputation and history of Damascus steel has given rise to many legends, such as the ability to cut through a rifle barrel or to cut a hair falling across the blade,[5] but no evidence exists to support such claims. A research team in Germany published a report in 2006 revealing nanowires and carbon nanotubes in a blade forged from Damascus steel.[6] This finding was covered by National Geographic[7] and the New York Times.[8] Although certain types of modern steel outperform these swords, chemical reactions in the production process made the blades extraordinary for their time, as damascus steel was superplastic and very hard at the same time. During the smelting process to obtain Wootz steel ingots, woody biomass and leaves are known to have been used as carburizing additives along with certain specific types of iron rich in microalloying elements. These ingots would then be further forged and worked into Damascus steel blades, and research now shows that carbon nanotubes can be derived from plant fibers,[9] suggesting how the nanotubes were formed in the steel. Some experts expect to discover such nanotubes in more relics as they are analyzed more closely.

Urushi Varnish

Reference Source: by Russ Stutler December, 2002 http://www.stutler.cc/pens/wajima/urushi.html

Urushi (pronounced "oo-roo-shee") is one of the most durable natural lacquers known to man. Urushi lacquered ornaments including bracelets have been discovered in Japan dating from the Jomon period 9,000 years ago. In the west, these objects are also referred to as "japaned" objects. Hardened urushi is water and acid proof, and also protects the object from heat, salt, mold and mildews and all types of weathering. It has been used on wood, pottery, bone, baskets, fabric and metal. Recently it has been successfully applied to the barrels and caps of fountain pens made of ebonite (black hard rubber) .

Urushi (pronounced "oo-roo-shee") is one of the most durable natural lacquers known to man. Urushi lacquered ornaments including bracelets have been discovered in Japan dating from the Jomon period 9,000 years ago. In the west, these objects are also referred to as "japaned" objects. Hardened urushi is water and acid proof, and also protects the object from heat, salt, mold and mildews and all types of weathering. It has been used on wood, pottery, bone, baskets, fabric and metal. Recently it has been successfully applied to the barrels and caps of fountain pens made of ebonite (black hard rubber) .

Urushi is not only a durable varnish but is also one of the strongest adhesives while it is wet, which makes it perfect for decorating with gold powder (maki-e) gold foil (chinkin) or mother of pearl inlays (raden). It is so strong an adhesive that in the distant past urushi was used by hunters and warriors to fix arrowheads to their arrow shafts!

This strength combined with the natural beauty of urushi lacquer ware is the reason it has been so popular for thousands of years.

When we hear of urushi lacquerware, we think of shiny objects such as boxes and bowls covered with gold or colored maki-e decorations. However, the idea of decorating on top of urushi is a relatively new idea. Until the 18th century, urushi lacquer ware was quite plain with no decoration. Red or black urushi was used on a wide variety of objects from household necessities such as rice bowls, sake cups and combs to hunting tools. Swords, shields and entire body armor had coatings of urushi!

Constructive criticism and comments welcome.

This email address is being protected from spambots. You need JavaScript enabled to view it.