|

|

We market genuine, top quality Takane quartz clock movements equipped with an on/off switch and mechanism advance wheel. (Note there are cheaper clones available which do not have these features which are very useful for setting hands and maintenance operations such as cleaning).

These movements can be used in numerous projects with clock faces made from many different materials. Popular choices include old LP records, hub caps and pottery and crockery pieces, the choice is basically yours, all you need to be able to do is establish the correct shaft length of your movement to suit the clock body, drill a 8mm central hole (shaft diameters are a standard 8mm) and find somewhere to hang it!

The Takane movements will serve as a replacement movement for numerous commercially made clocks where the movement has reached the end of its service life. For this end we offer purchase options without hands and numerals. Note that we will supply an average set of hands and numerals for customers who purchase a movement WITH hands and numerals and who omit to specify their preference. If you want your choice of hands and numerals please order them when you order your movement(s).

SEE HERE - For Standard mechanisms

SEE HERE - We now offer High Torque clock mechanisms capable of driving hands suited to large clocks up to a metre in diameter!

SEE HERE - We now offer Pendulum movements

Decisions

1. If you need a replacement mechanisn only and wish to re-use your existing hands these options may well replace a deceased Takane mechanism but other brands may use different hand attachment.

2. Decide on the optimum shaft length which is determined by the thickness of the clock face. You should allow a minimum of 2mm of protruding threaded shaft to fit the main mechanism mounting nut so an 8mm shaft is appropriate to a 6mm thick face, a 15mm shaft is good for 12 or 13mm thick face and a 23mm shaft would suit clock faces made from material around 20mm thick. If you have an excess of shaft then a packing made of something like stiff cardboard can be used instead of the black rubber washer supplied in the mounting kit with every movement.

3. Decide whether you need hands (29 options), numerals (16 options), a second hand (3 colour options) or a closed shaft cap nut used instead of a second hand.

4. Do you need a hanger?

Purchasing your standard Clock Assembly

Follow the link below to assemble your clock parts kit. You will be offered in turn your choice of mechanism, hands (or none), numerals (or none) etc

http://www.thewoodworks.com.au/shop/project-components/clock-movements

Check Contents

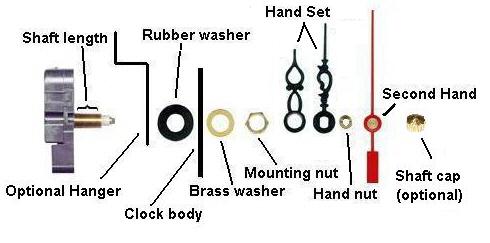

Refer to the parts diagram above.

All mechanisms are supplied with a set of mounting hardware - 1 each of plastic black cushion washer, brass washer, larger shaft nut and smaller brass second hand nut.

Before opening the inner plastic bag with the hardware check that contents are complete! It is very easy to misplace small items.

Optional Components

Note that the hanger and the shaft cap (used in lieu of a hand nut and second hand) are optional purchases. Replacement or additional mounting kit sets are also available.

Assembly

Clock movements require a 2A battery (not supplied) and assembly is simple. Refer to the exploed parts diagram above. If ordered with the kit, fit the hanger (which can be omitted if desired) against the clock body, then slide on the rubber washer and insert the clock body, hanger and rubber washer into the back of the clock face (into which you may have made a suitable rear recess).

At the front, slide on the brass washer and then fit and gently tighten up the mounting nut. DO NOT over tighten the mounting nut as this may damage the movement. The hour hand is pressure fitted next followed by the minute hand which has registration flats so take care here to correctly engage the flats on the hand to the matching flats on the mechanism shaft.

For asemblies with a sweep second hand, fit the hand nut next to secure the minute hand (this needs a delicate touch to prevent cross threading) and then wait before press fitting the second hand until Initial Hands Adjustment below. This will allow the second hand to step right on 12 o'clock.

For assemblies without a sweep second hand fit the brass shaft cap.

Initial Hands Adjustment

With clock switched OFF, use the mechanism advance wheel and manually rotate the minute hand clockwise (of course!) to 12 o'clock, then gently force the hour hand (which is a friction fit and does not have a keyed shaft) also to 12 o'clock. Finally now press in the second hand also at 12 o'clock, insert the battery taking care to get the polarity correct and switch clock ON.

Setting the Time

It is best practice to switch the clock OFF, adjust the clock to the current time by using the advance wheel on the back (best not to use your finger to wind the minute hand manually) and then switch the clock on.

The quartz movement is 55mm square and 75mm across the diagonals which will need, if your design requires, a circular recess of 75mm diameter. You can of course drill a grid of overlapping holes in materials such as wood using a somewhat smaller forstner type bit than 75mm to avoid the expense of a 75mm forstner style bit. A square recess needs to be 56mm x 56mm. The recess should be at least 16mm deep to fully house the movement. If you use a hanger make the recess 16 to 17mm deep.

Extra Large Clocks

Note that these mechanisms will work fine with the hand lengths offered. They are NOT intended for use with larger, heavier or extended hand sets.

SEE HERE - We now offer High Torque clock mechanisms capable of driving hands suited to large clocks up to a metre in diameter.