The built world is in many instances held together by nut and bolt fasteners which come in a myriad of styles and designs, in a great many metals and plastics and in at least a dozen or so extant thread standards with historically many more which are more or less redundant.

The first bolts and matching nuts date to at least 400 years ago. Over the centuries competing standards have vied for acceptance and dominance.

For Australian readers there are broadly two groups of thread standards of interest - the INCH based (sometimes referred to as Imperial) and the METRIC based. These are incompatible.

Following the earlier adoption of decimal currency in 1966 - the jingle remains with me - to the tune of Click Go The Shears - "Out go the pounds, the shillings and the pence on the fourteenth of February 1966" , the conversion to metric weights and measures began in 1971. Wiki Link

In essence a decimal system uses whole parts and parts of the whole defined decimally - e.g a 25.5mm describes 25 full millmetres and a half of one millimetre whereas an inch system typically is defined fractionally by full inches and the fractional parts of a whole inch. e.g. 1-29/64ths describes one full inch and an additional 29 times that of a sixty fourth of an inch.

(Inches can of course be defined decimally - a machinist I work with defends and prefers working to the thousanth of an inch - the 'thou'). There are other inch based measures which survive because they happen to be more elegant in use - an example is a traditional inch based wood volume measure of a 'super foot' which is 144 cubic inches or 12 x 12 x 1 inch. A 'super foot' is probably better comprehended than a cubic metre. Quoting the cost of a stick of wood as $10 a super foot compared to the quivalent $4,250 a cubic metre illustrates this.

In practice, using the above examples, how much easier is it to comprehend that 25.5mm is shorter than 25.6mm compared to figuring out which is larger 29/64ths or 11/32nds of an inch?

Digression: See some Reckoner Tables HERE.

THREAD ELEMENTS & STANDARDS

Note: By worldwide convention bolt or machine screw diameter measurements are nominal. If you caliper a 10mm bolt you will see it is in fact slightly less than 10mm. If you are working with a 10mm drill to fit a 10mm screw the drill will be 10mm, the screw will be a clearance fit for the 10mm hole and something like 9.85mm.

- Style - BOLTS have a part threaded shank, SET SCREWS are fully threaded.

- Type - We market Countersunk Head, Hexagonal Head and Cheese Head screws. There are numerous other Types.

- Diameter - Nominal. Described in either inches often using fractions - e.g 1/2 inch or in millimetres 12mm

- Length - Described in either inches often using fractions - e.g 1-1/2 inch or millimetres 35mm. Countersunk set screws measure overall, Hex and Cheese Head set screws measure from under the head.

- Metric Tooth Count - Metric fasteners use PITCH - the distance between adjacent teeth in mm - e.g M6 x 1.0mm is a standard metric coarse thread with teeth every one mm. In this case one turn of the screw advances the screw 1mm.

- Inch Tooth Count - Inch sizes use TEETH PER INCH (TPI) - e.g 5/16 x 18tpi is a standard UNC description for a 5/16 inch bolt with 18 threads to the inch.

- Gauges For Smaller UNC Sizes - The inch thread standard in most common use - UNC, Unified Coarse - anachronistically uses wire gauge descriptions for sizes 1/4 of and inch and smaller - e.g what Australians know as a 3/16th inch screw will be specified as a 10-24 in US references.

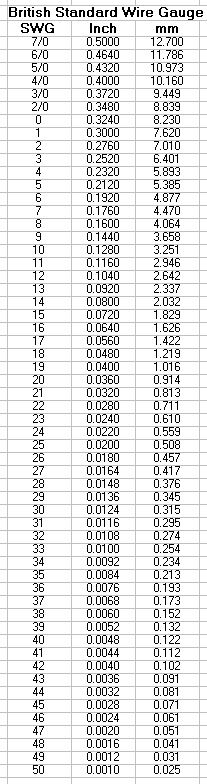

- Wire Gauges - A diameter measure rooted in an inch world that finds fractions clumsy - see a SWG Table below - and still widely employed describing wood screws.

- Coarse, Fine, Extra Fine - are variants of a parent - e.g a British Standard Whitworth has a BSW Coarse and a BSF Fine and UNC has companions UNF - Unified Fine and UNEF Unified Extra Fine.

- Head & Nut Dimensions - Metric Hex Head screws have a standard simple measurement for each size across the flats of the head and matching nut - the AF measure.

- Thread Angle - Metric fasteners have a 60 degree thread angle, Inch thread screws typically have a 55 degree thread angle - a key difference in compatibility.

- UNC & BSW Compatibility - in sizes up to but excluding 1/2 inch British Standard Whitworth (the Grandfather of thread standards) is compatible with UNC.